|

|

|

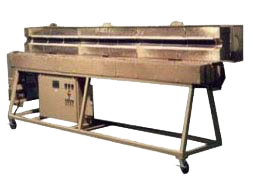

This High Temperature IR Oven is 20 feet long and has no conveyor. It can produce temperatures up to 1000 degrees Fahrenheit. It was used to cure silicone

|

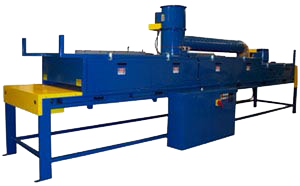

This IR oven was designed and fabricated to cure waterborne adhesive on flocked paint pads. The energy had to penetrate a long white fiber and to cure the adhesive on a soft foam rubber sheet.

|

| |

|

|

|

This IR oven was designed and fabricated to cure a flocking adhesive applied to a thermoplastic product whereby the appropriate heat had to be applied to cure the adhesive and excess heat could not be applied so as to distort the plastic.

|

Infrared/Hot Air Curing Oven for Rubber products. Front & Rear views of the oven.

|

| |

|

|

|

|

High Velocity Hot Air Curing System for rubber extrusions.

|

| |

|

Preheaters

|

|

EIS builds a variety of pre-heaters. These are used to preheat steel, fabric, wire or other materials that may be cross-headed at the extruder. Preheating these materials allows the rubber or plastic to adhere better to the material. Pre-heaters are also effective at taking moisture out of cloth or woven products prior to cross-heading. This reduces blisters in the rubber. Pre-heaters can also be used to dry adhesive, coatings, achieve some skin cure prior to laying a product on a belt so that it does not get belt marks. Depending on the application the length and KW are determined to provide the best solution.

|

| |

|

|

| |

|

|

|

Wire Pre-Heater

|

|